Wrench (tool): Difference between revisions

imported>Milton Beychok m (Formatting for Featured Article Candidate) |

mNo edit summary |

||

| (24 intermediate revisions by 7 users not shown) | |||

| Line 1: | Line 1: | ||

{{subpages}} | {{subpages}} | ||

{{TOC|right}} | {{TOC|right}} | ||

A '''[[Wrench (tool)|wrench]]''' ([[American English]]), or '''spanner''' ([[British English]]), is a [[fastening tool]] used to manipulate threaded fasteners such as [[nut (fastener)|nut]]s, [[stud (fastener)|stud]]s and [[bolt (fastener)|bolt]]s. They also may manipulate threaded structural elements such as pipes. The wrench is sized and shaped to put pressure and leverage on flat faces of the fastener, and then is moved in the direction of rotation needed to loosen or tighten the fastening assembly. | |||

A | |||

==Hand tools== | |||

The most common hand wrenches are made either from a flat bar of steel, or from cylinders. Even with these two types, the wrench can either completely or partially surround the fastener. | The most common hand wrenches are made either from a flat bar of steel, or from cylinders. Even with these two types, the wrench can either completely or partially surround the fastener. | ||

===Flat Bar=== | |||

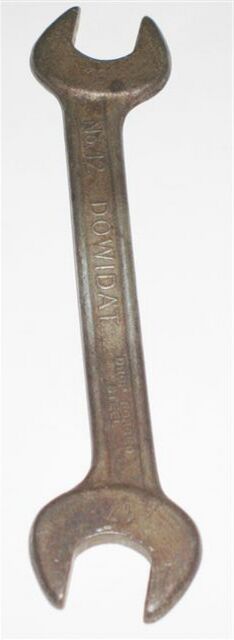

The most common hand wrenches either are open-ended, such that they have sides parallel to two or more facets of the nut, or box, which surrounds all sides of the nut. These types can drop over the nut no matter how much of the screw or bolt protrudes. | |||

The most common hand wrenches either are open-ended, such that they have sides parallel to two or more facets of the nut, or box, which surrounds all sides of the nut. These types | |||

The longer the handle of the wrench, the more force can be applied to the fastener. One technique is to carry a length of pipe, which can slip over the wrench and act as a handle extender. Do be warned, however, that a sufficiently long pipe can exert enough force to break the wrench or the fastener. | |||

{{Image|Open end wrench.jpg|right|250px|Double-sided open-end wrench}} | |||

{{Image|Box-end wrench.jpg|right|250px|Double-sided box-end wrench}} | |||

Still, there are times when it is absolutely necessary to release a stuck fastener. It is usually wise first to apply a penetrating lubricant to the fastener, and tap it gently to let the lubricant reach the threads, waiting briefly before applying force. Yet another dangerous but sometimes necessary technique is to hit the handle of the wrench with a hammer; do remember to hit it in the direction in which the fastener needs to turn. Gloves and eye protection are wise precautions when hammering a wrench. An even more desperate expedient is to heat the fastener to expand it, which may destroy the hardness or toughness of the metal. Occasionally, it is possible to chill the piece to which the fastener is attached, contracting it and helping break the adhesion. | Still, there are times when it is absolutely necessary to release a stuck fastener. It is usually wise first to apply a penetrating lubricant to the fastener, and tap it gently to let the lubricant reach the threads, waiting briefly before applying force. Yet another dangerous but sometimes necessary technique is to hit the handle of the wrench with a hammer; do remember to hit it in the direction in which the fastener needs to turn. Gloves and eye protection are wise precautions when hammering a wrench. An even more desperate expedient is to heat the fastener to expand it, which may destroy the hardness or toughness of the metal. Occasionally, it is possible to chill the piece to which the fastener is attached, contracting it and helping break the adhesion. | ||

| Line 21: | Line 17: | ||

====Combination wrench==== | ====Combination wrench==== | ||

A combination wrench has a one open and one box end, usually of the same size. The open end is more useful when there is limited access to the fastener. Box ends can get a better grip when the flats of the nut are deformed. | {{Image|Combination wrench.jpg|right|250px|A combination wrench}}A combination wrench has a one open and one box end, usually of the same size. The open end is more useful when there is limited access to the fastener. Box ends can get a better grip when the flats of the nut are deformed. | ||

====Adjustable open wrench==== | ====Adjustable open wrench==== | ||

{{Image|Bahco.jpg|left|250px|Adjustable wrench}} | |||

An adjustable wrench has one fixed jaw, and one that is adjustable by means of a [[screw (mechanical)|screw adjustment]], usually made in one piece with the adjustable jaw. In the U.S., this is often called a Crescent wrench after the first well-known manufacturer, while it is a Bahco wrench in Dutch usage, after the Swedish manufacturer. The obvious advantage of the adjustable wrench is that an entire set of wrenches need not be carried when the size of the fastener to be adjusted is not known. The disadvantage is that the adjustment can slip, and generally cannot apply as much force as a solid wrench. | |||

It should be mentioned, if mostly to condemn the practice, that [[pliers]] are sometimes used to adjust nuts. Most types of pliers, however, do not have parallel jaws, but angled ones. These are apt to deform a nut if heavy pressure is applied. | It should be mentioned, if mostly to condemn the practice, that [[pliers]] are sometimes used to adjust nuts. Most types of pliers, however, do not have parallel jaws, but angled ones. These are apt to deform a nut if heavy pressure is applied. | ||

===Pipe wrench=== | ===Pipe wrench=== | ||

{{Image|Pipe wrench.jpg|right|250px|Pipe wrench}} | |||

Pipe wrenches grasp threaded pipes and turn them, so they do not have flat jaws. One common type has curved jaws, with the wrench designed to slip slightly so it can be repositioned as the pipe moves under it. These were called Stillson wrenches after the inventor; they are sometimes, incorrectly, called monkey wrenches. | Pipe wrenches grasp threaded pipes and turn them, so they do not have flat jaws. One common type has curved jaws, with the wrench designed to slip slightly so it can be repositioned as the pipe moves under it. These were called Stillson wrenches after the inventor; they are sometimes, incorrectly, called monkey wrenches. | ||

| Line 37: | Line 36: | ||

Sockets proper are single pieces of cast or machined metal, with one end shaped to slip over the fastener to be manipulated, and the other to receive a driveshaft to turn it. The shaft end may actually have a depression, or even a spring-loaded bearing, to help lock the shaft into place. In combination, the driveshaft and socket are extremely strong in rotation, but should separate easily with linear traction. | Sockets proper are single pieces of cast or machined metal, with one end shaped to slip over the fastener to be manipulated, and the other to receive a driveshaft to turn it. The shaft end may actually have a depression, or even a spring-loaded bearing, to help lock the shaft into place. In combination, the driveshaft and socket are extremely strong in rotation, but should separate easily with linear traction. | ||

Where the English measurement system is used, the shaft diameter is most often 3/8" or 1/4" for general purposes. 1/2", 3/4", and 1" drives are used for heavy equipment. Both metric and English system sockets, however, can snap onto the male end of the shaft. | Where the English [[Systems of measurement|measurement system]] is used, the shaft diameter is most often 3/8" or 1/4" for general purposes. 1/2", 3/4", and 1" drives are used for heavy equipment. Both metric and English system sockets, however, can snap onto the male end of the shaft. | ||

Adapters are available to convert between shaft sizes. For example, one might have a large nut but only a 1/4" shaft system, so an adapter can allow a 3/8" socket to be used with that shaft. | Adapters are available to convert between shaft sizes. For example, one might have a large nut but only a 1/4" shaft system, so an adapter can allow a 3/8" socket to be used with that shaft. | ||

| Line 66: | Line 65: | ||

===Power torque wrench=== | ===Power torque wrench=== | ||

Intended for industrial applications, these are often powered hydraulically, which allows great precision. | Intended for industrial applications, these are often powered hydraulically, which allows great precision. | ||

[[Category:Suggestion Bot Tag]] | |||

Latest revision as of 12:00, 9 November 2024

A wrench (American English), or spanner (British English), is a fastening tool used to manipulate threaded fasteners such as nuts, studs and bolts. They also may manipulate threaded structural elements such as pipes. The wrench is sized and shaped to put pressure and leverage on flat faces of the fastener, and then is moved in the direction of rotation needed to loosen or tighten the fastening assembly.

Hand tools

The most common hand wrenches are made either from a flat bar of steel, or from cylinders. Even with these two types, the wrench can either completely or partially surround the fastener.

Flat Bar

The most common hand wrenches either are open-ended, such that they have sides parallel to two or more facets of the nut, or box, which surrounds all sides of the nut. These types can drop over the nut no matter how much of the screw or bolt protrudes.

The longer the handle of the wrench, the more force can be applied to the fastener. One technique is to carry a length of pipe, which can slip over the wrench and act as a handle extender. Do be warned, however, that a sufficiently long pipe can exert enough force to break the wrench or the fastener.

Still, there are times when it is absolutely necessary to release a stuck fastener. It is usually wise first to apply a penetrating lubricant to the fastener, and tap it gently to let the lubricant reach the threads, waiting briefly before applying force. Yet another dangerous but sometimes necessary technique is to hit the handle of the wrench with a hammer; do remember to hit it in the direction in which the fastener needs to turn. Gloves and eye protection are wise precautions when hammering a wrench. An even more desperate expedient is to heat the fastener to expand it, which may destroy the hardness or toughness of the metal. Occasionally, it is possible to chill the piece to which the fastener is attached, contracting it and helping break the adhesion.

For some specialized applications, typically where only authorized persons are to adjust the fastener, the sides of the wrench head may not be parallel. For example, the nuts on fire hydrants are pentagonal, so they cannot be manipulated with a standard wrench shape.

Combination wrench

A combination wrench has a one open and one box end, usually of the same size. The open end is more useful when there is limited access to the fastener. Box ends can get a better grip when the flats of the nut are deformed.

Adjustable open wrench

An adjustable wrench has one fixed jaw, and one that is adjustable by means of a screw adjustment, usually made in one piece with the adjustable jaw. In the U.S., this is often called a Crescent wrench after the first well-known manufacturer, while it is a Bahco wrench in Dutch usage, after the Swedish manufacturer. The obvious advantage of the adjustable wrench is that an entire set of wrenches need not be carried when the size of the fastener to be adjusted is not known. The disadvantage is that the adjustment can slip, and generally cannot apply as much force as a solid wrench.

It should be mentioned, if mostly to condemn the practice, that pliers are sometimes used to adjust nuts. Most types of pliers, however, do not have parallel jaws, but angled ones. These are apt to deform a nut if heavy pressure is applied.

Pipe wrench

Pipe wrenches grasp threaded pipes and turn them, so they do not have flat jaws. One common type has curved jaws, with the wrench designed to slip slightly so it can be repositioned as the pipe moves under it. These were called Stillson wrenches after the inventor; they are sometimes, incorrectly, called monkey wrenches.

Another type does not have jaws, but instead a chain that tensions against the pipe.

Some plumbing fixtures have a nut-like shape molded into the metal, so that a flat-jawed wrench can be used. This is the application intended for the increasingly rare monkey wrench.

Socket wrenches and nutdrivers

Sockets proper are single pieces of cast or machined metal, with one end shaped to slip over the fastener to be manipulated, and the other to receive a driveshaft to turn it. The shaft end may actually have a depression, or even a spring-loaded bearing, to help lock the shaft into place. In combination, the driveshaft and socket are extremely strong in rotation, but should separate easily with linear traction.

Where the English measurement system is used, the shaft diameter is most often 3/8" or 1/4" for general purposes. 1/2", 3/4", and 1" drives are used for heavy equipment. Both metric and English system sockets, however, can snap onto the male end of the shaft.

Adapters are available to convert between shaft sizes. For example, one might have a large nut but only a 1/4" shaft system, so an adapter can allow a 3/8" socket to be used with that shaft.

Basic handle and extension

The most basic driver is a shaft with a handle, much like a screwdriver, but with a socket-mating connector rather than a screwdriver bit. Another very common variant, called an extension, has a male connector that mates with the socket at one end, and a female connector that accepts another socket tool at the other. Multiple extensions can be snapped together for extra length.

Nutdrivers

Nutdrivers are a permanently attached set of socket, driveshaft, and handle. Some nutdrivers have hollow shafts, so bolt length protruding above the nut goes into the hollow and does not interfere with rotation.

Aids to leverage

Most often, however, at the end of the extension away from the socket, a tool to improve the leverage of driving is attached. One such tool is a ratchet, which, at first, looks like an open-ended or box wrench. The male connector, however, is attached to a disk and mechanical components inside the ratchet head. There is a small control that selects the direction (i.e., loosening or tightening) in which the socket is to be moved. Once that control is set, the ratchet moves freely in the other direction, so it can be repositioned easily; it is not necessary to have 360 degree access above the fastener -- just enough working space to move the ratchet handle.

Other ways to improve leverage include various pivoting handles. One type looks like the brace (tool) used to drive hand drills; there is a socket fitting rather than a chuck at the working end. The operator holds a knob, fitted with bearings in which the shaft turns, and cranks a handle.

Another type, called a flex handle, is related to the rachet, but, rather than rotating, the handle pivots 180 degrees so it can be repositioned quickly. A flex handle is simpler, cheaper, and may be able to apply more force than a rachet.

Torque wrenches

A torque wrench is both a fastening tool and a measuring device. It is used where precise measurement of the tightness of a bolt is necessary.

It has been suggested that a quantum mechanical torque wrench can measure either the torque, or find the bolt, but not both.

Spanners (precision)

While a spanner is a general term in British English for "wrench", there is a specialized tool always known as a spanner. It consists of a bar with two or more protruding pins, sometimes adjustable in distance, that fit into corresponding holes in a fastener an allow it to be turned. The bar is connected to a shaft or other mechanism to allow turning, or sometimes the spanner is built not as a bar, but as a pliers-like device with the pins at the work end. Spanners are often used in optical work, on the retaining rings of lens elements.

Power wrenches

Impact wrenches

One of the most common types is a power-operated driver for sockets, the sockets usually made of extra-strong metal. Pneumatically driven impact wrenches are extremely common in the automotive industry; air drive does not generate the sparks that an electric motor could produce, which would be hazardous in the presence of petroleum products.

For other applications, however, electric impact wrenches are increasingly common, especially cordless battery-powered wrenches with great portability. For some heavy applications, the impact energy may be provided by an explosive cartridge.

There are impact wrenches that are hand-powered, but by hitting a specific part with a hammer, allowing great force to be applied.

Power torque wrench

Intended for industrial applications, these are often powered hydraulically, which allows great precision.